匠心工艺

Craftsmanship with ingenuity

Master craftsmanship,

passed down from generation to generation,

the beauty of Ru porcelain lies in its warm glaze color and exquisite production.

production process

原料开采

Raw material extraction

The unique kaolin mine in Ruzhou, Henan Province, is rich in sericite and is the cornerstone of Ru porcelain’s sky blue color. The ore has a delicate texture and contains unique mineral components, laying the groundwork for the subsequent firing of a warm and jade like sky blue glaze surface.

粉碎筛选

Crushing and screening

The ore is sieved three times to a fineness of 200 mesh to obtain pure porcelain clay. The 2020mm sieve is used to screen layer by layer, removing impurities and making the porcelain clay as fine as grease, laying a solid foundation for the dense and smooth appearance of the Ru porcelain body.

制浆沉淀

Pulping sedimentation

Take porcelain clay and mountain spring water, mix them thoroughly in a ratio of 1:2, let them stand for 72 hours, and let them settle naturally to complete purification. The process relies on natural standing to achieve porcelain clay purification.

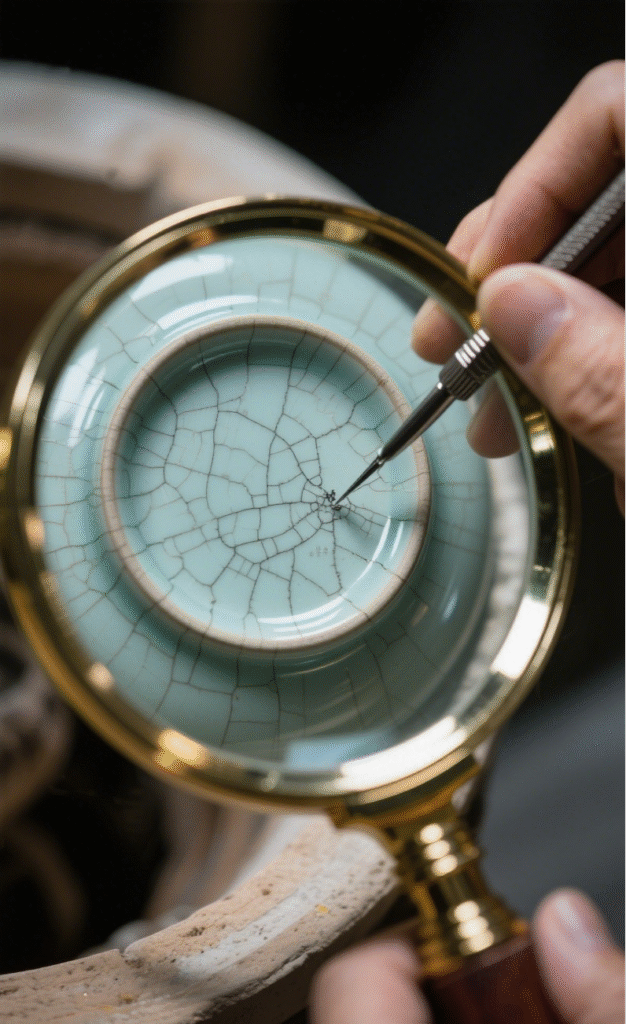

装饰刻画

Decorative carving

The craftsman holds a slanted mouth carving knife and uses the “half blade mud” technique to wander around the blank. The blade enters the mud by 0.5 millimeters, with one side deep and the other shallow, forming a hidden slope. After the glaze is fired, the thickness of the glaze layer flows with the knife marks, and the patterns seem to float on the sky blue glaze surface, creating a three-dimensional effect.

施釉工序

Glazing process

The craftsman takes an appropriate amount of glaze slurry and pours it into the blank, using their wrist to gently rotate the object, using the fluidity of the glaze slurry to “sway” the inner and outer walls. Through precise control, the glaze layer is evenly applied to the body, with a stable thickness of 0.8 millimeters, laying the foundation for the beauty of sky blue.

素烧定型

Vegetarian firing molding

In the firing process, the body is subjected to 12 hours of high-temperature quenching in the kiln, which significantly improves its strength and lays a solid foundation for subsequent glaze application. It effectively avoids the risk of deformation caused by uneven stress after glaze application and is a key step in protecting the formation of Ru porcelain.

出窑检验

Kiln inspection

Ru porcelain products need to undergo three inspections: tapping, looking, and touching. Tap lightly and listen to whether the opening is crisp and pleasant; Carefully observe whether the glaze color and texture of the cracks are even and clean; Touch to feel the thickness of the body and whether the enamel is warm and moist. Only when the three inspections are qualified can it be considered as a superior product.